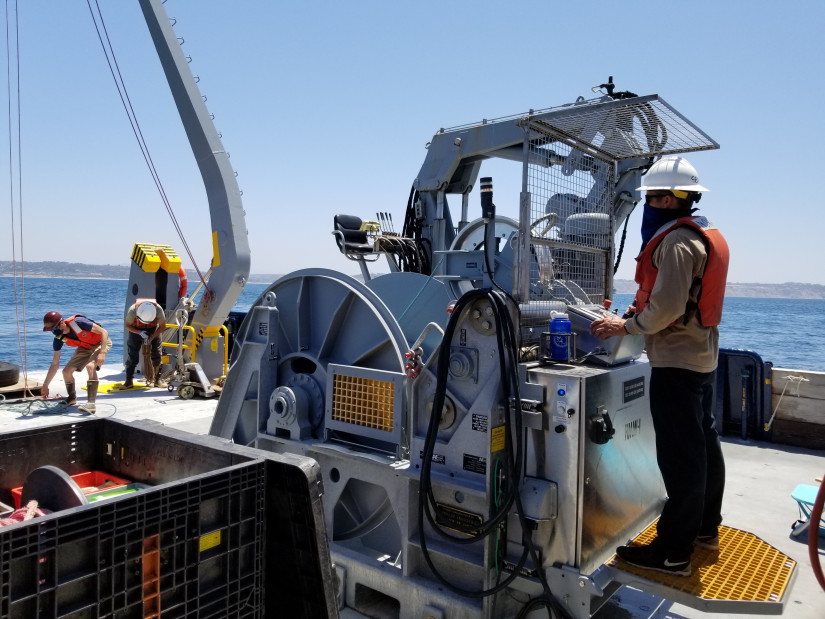

DESCRIPTION: The Hawboldt Mooring Winch (HMW), model SPRE-3464, is a portable general-purpose winch to be used for any type of deployment. The winch frame is designed to fit the UNOLS standard 2’x2’ bolt pattern and has lift points for equal length slings and fork pockets. The electrical controls panel and braking resistor are integrated into the winch skid and require a single point power connection making installation quick and easy. It is a single drum, direct pull type unit driven by a right-angle helical bevel gearbox and totally enclosed non-ventilated (TENV) electric motor with integral failsafe. The failsafe brake is a parking brake only and should not be used for dynamic braking. Dynamic braking is achieved through the variable frequency drive and braking resistor.

The winch has a hollow stub shaft to accommodate a Focal 180 model slip ring. If using a slip ring the cable should connect to the slip-ring inside winch drum where there are a few service loops of cable before it is clamped to a fixing point.

The winch has a smooth drum so that it can accommodate various sized cable and line hardware. The cable is passed through a hole in the drum barrel along the flange and clamped on the inside of the barrel.

The winch uses a PLC controlled in-line levelwind which is capable of variable speeds for spooling cable of various diameters. The levelwind includes a sheave with large curved aluminum cheek plates for passing line hardware up to 6” diameter. The sheave contains sensors for payout and line speed data, as well as a load pin in the axle for tension measurement. A lead screw, driven by helical-bevel gearbox and electric motor, is used to traverse the level wind sheave across the drum. Sensors measuring drum and screw rotation are used to control the levelwind position and Hawboldt spooling system is used to manage the levelwind from the HMI on the control console. The levelwind can also be parked for deployments where it is not required to pass the cable through the sheave.

The winch is controlled from a control console mounted on the winch which houses operator devices as well as Hawboldt’s sunlight readable HMI interface. This console gives full control and monitoring of winch and levelwind. A wired remote belly pack is also supplied that can be connected to the winch. Remote control is limited to winch operation only with limited monitoring (no HMI).

APPLICATION(S): While this winch has many applications as a general purpose oceanographic winch, it is particularly suited to deployment/recovery of moorings and instrument strings.

SPECIFICATIONS: see link to specification sheet below

Links to:

HMW Specifications (Quick Reference)

HMW General Arrangement Drawing

HMW Maximum Capacity Document (MCD)

PHOTOS

- R/V Sally Ride

-

R/V Roger Revelle

-

Handbook

- Section 1: Welcome Aboard

- Section 2: Specifications

- Section 3: Vessel Layout Description

- Section 4: Ship's and Scientific Equipment Description

- Section 5: Technical Services and Special Equipment

- Section 6: Navigation and Communications Capability

- Section 7: Safety

- Section 8: Ship Organization

- Section 9: Scientific Berthing Plan

- Specifications

- Schematic Drawings

- Berthing Plan

- Scientific Equipment

- Major Shipboard Equipment

-

Handbook

- R/V Robert Gordon Sproul

- R/V Bob and Betty Beyster

- Emeritus: R/V Melville

- Emeritus: R/V New Horizon

- Research Platform FLIP (FLoating Instrument Platform)

- Preventing harassment and discrimination

- Alcohol and illegal drugs: Zero tolerance

- Departure & arrival times

- Pregnancy and Lactation at Sea

- Accommodating Disabilities

- Minimum Age At Sea

- Isotope Use on Scripps Ships

- Geophysical survey requirements in California waters

- Export controls and compliance

- Scientific shipments to Scripps vessels

- Ship to Shore Communications

- Internet use policy

- Winch and Wire Regulations

- Ship Usage Rates

- Data and Sample Distribution Policy

- Stable Isotopes on SIO Ships

- Carryforward of Ship Time

- Using non-UNOLS vessels

- Transportation Worker's Identification Credential (TWIC)

- Naval Clearances

- Notice to mariners

- Volunteering Aboard Scripps Ships

- USCG Rules for Buoys